In an era where sustainability is paramount, understanding the environmental impact of everyday items is crucial. Cables, ubiquitous in modern life, are no exception. From manufacturing to disposal, every stage of a cable’s lifecycle can affect our ecosystem. Let’s delve into how different cable materials impact the environment and explore sustainable alternatives.

The Role of Cables in Modern Society

Cables are the backbone of our digital infrastructure, facilitating communication, power transmission, and data transfer. As technology advances, the demand for cables grows, amplifying their environmental footprint.

Growth in Cable Demand

The proliferation of electronic devices, telecommunications networks, and renewable energy systems drives the increasing demand for cables worldwide.

Impact on Resource Consumption

The exponential growth in cable production results in higher resource consumption, including raw materials and energy.

Manufacturing Processes and Environmental Implications

The production of cables involves extracting raw materials, refining metals, and manufacturing plastic components. These processes consume energy, generate waste, and contribute to greenhouse gas emissions.

Energy Consumption in Cable Manufacturing

The energy-intensive nature of cable manufacturing, particularly in metal refining and plastic extrusion, contributes to carbon emissions and resource depletion.

Waste Generation and Pollution

The disposal of by-products from cable production, such as plastic waste and metal sludge, poses environmental risks such as pollution and habitat degradation.

Plastic vs. Metal Cables: A Comparative Analysis

Plastic cables, commonly made from PVC (polyvinyl chloride), and metal cables, predominantly composed of copper or aluminum, have distinct environmental impacts. Assessing their lifecycle emissions and resource consumption is essential for informed decision-making.

Environmental Footprint of PVC Cables

PVC cables exhibit a high carbon footprint due to the energy-intensive manufacturing process and the release of toxic emissions during production and disposal.

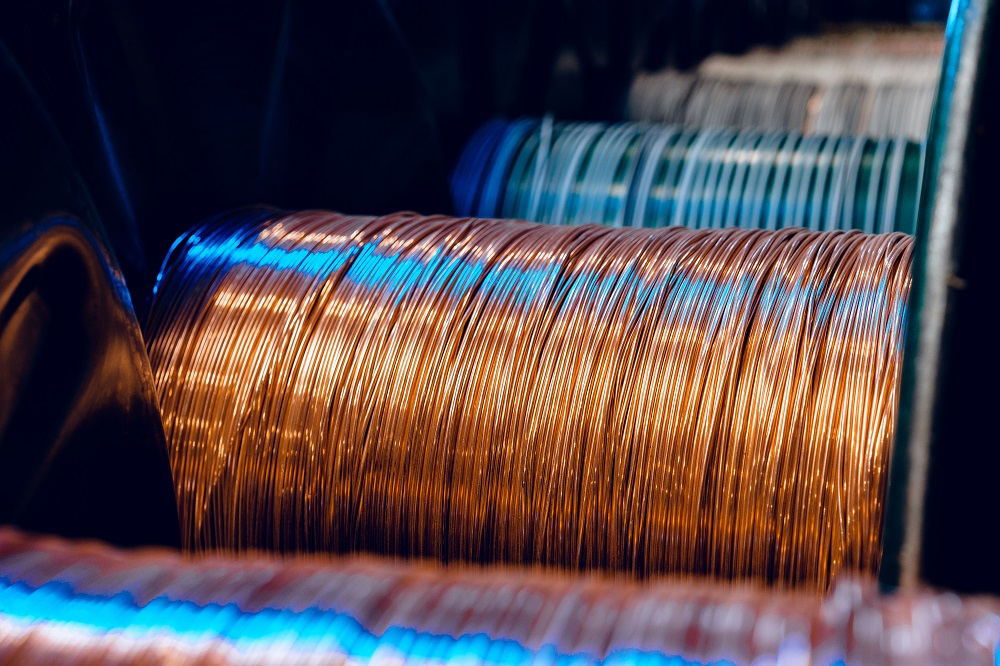

Ecological Impact of Metal Cables

Metal cables, while durable and conductive, contribute to environmental degradation through mining operations, habitat destruction, and soil contamination.

PVC Cables: Environmental Concerns and Alternatives

PVC cables raise concerns due to their production’s reliance on fossil fuels and the release of harmful chemicals during manufacturing and disposal. Exploring eco-friendly alternatives, such as halogen-free cables, can mitigate these environmental risks.

Risks Associated with PVC Cable Production

The production of PVC cables involves the use of chlorine-based compounds and plasticizers, posing health risks to workers and environmental hazards.

Transition to Halogen-Free Cables

Halogen-free cables, manufactured using non-toxic materials and alternative insulation compounds, offer a sustainable solution to reduce environmental impact and health risks.

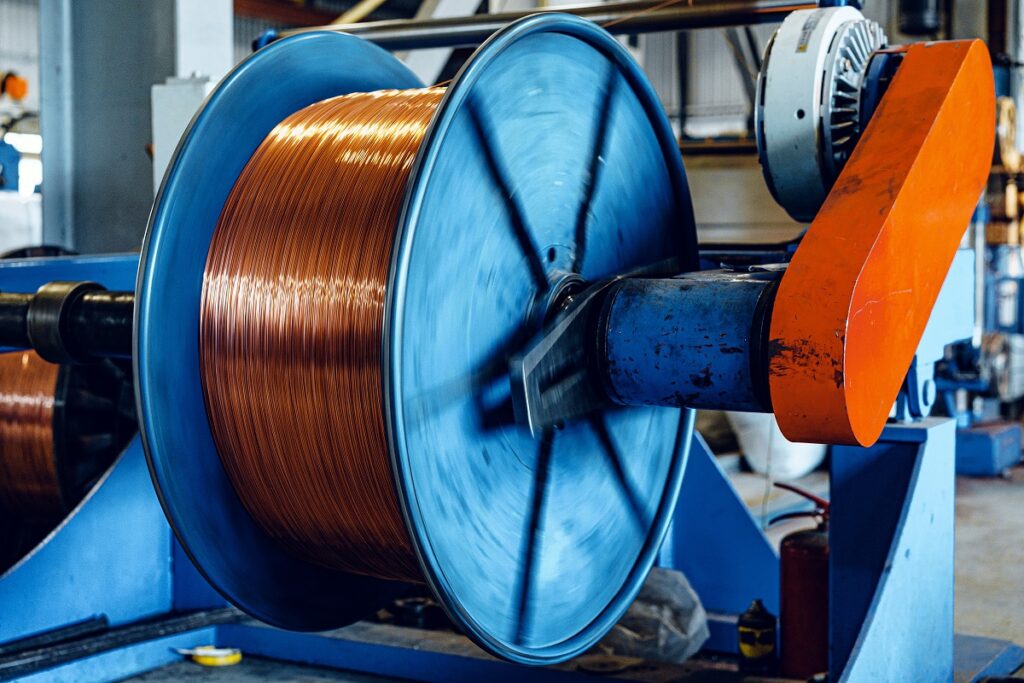

Metal Cables: Mining, Extraction, and Recycling

The extraction of metals like copper and aluminum involves mining, which can cause habitat destruction, soil erosion, and water pollution. Implementing efficient recycling programs is crucial to reduce the environmental impact of metal cables.

Environmental Impact of Metal Mining

The mining of metals for cable production contributes to deforestation, soil erosion, and water contamination, impacting ecosystems and biodiversity.

Benefits of Cable Recycling

Recycling metals from end-of-life cables reduces the need for virgin resources, conserves energy, and minimizes greenhouse gas emissions, supporting a circular economy.

Renewable and Recycled Materials in Cable Production

Advancements in technology have paved the way for cables made from renewable and recycled materials. Harnessing resources like bio-based polymers and reclaimed metals minimizes reliance on finite resources and reduces environmental degradation.

Sustainable Alternatives in Cable Manufacturing

The integration of renewable materials, such as bio-based polymers derived from plant sources, offers a sustainable alternative to traditional cable insulation materials.

Closed-Loop Recycling Systems

Implementing closed-loop recycling systems for cable materials enables the recovery and reuse of valuable resources, reducing waste and environmental impact.

About Pure CU: Wires and Cables

At Pure CU, we take pride in being a leading provider of fire and heat-resistant wires and cables, ensuring quality, reliability, and innovation since 1984. Based in Karachi, we are dedicated to delivering superior electrical solutions crafted with advanced manufacturing techniques and backed by four decades of expertise. Trust Pure CU to power your needs with products designed for excellence and safety.

Conclusion

In conclusion, the cable industry is undergoing a period of unprecedented innovation, driven by advancements in materials science, nanotechnology, and artificial intelligence. From fiber optic cables that transmit data at the speed of light to smart cables that monitor their own performance, these innovations are reshaping the way we connect and communicate. As we look to the future, one thing is certain: the evolution of cables will continue to play a central role in powering the digital age.