Understanding the critical role that insulation plays in the performance and safety of cables is paramount for engineers, electricians, and anyone involved in electrical systems. Cable insulation serves as a protective barrier, shielding the conductors from external factors that could compromise their integrity and safety. In this comprehensive guide, we will delve deeper into the various types of cable insulation, factors influencing insulation performance, and the crucial importance of proper insulation for cable safety and performance.

Exploring Cable Insulation

Cable insulation is the material used to cover electrical conductors, providing insulation and protection against a wide range of environmental and mechanical stresses. The choice of insulation material depends on several factors, including the voltage rating of the cable, environmental conditions, and specific application requirements.

Types of Cable Insulation Materials

Polyethylene (PE):

Polyethylene insulation is renowned for its excellent electrical properties and resistance to moisture and chemicals. It is commonly used in low to medium voltage applications where reliability and cost-effectiveness are paramount. PE insulation is available in various forms, including solid, foam, and semi-conductive options, allowing for versatility in different applications.

Cross-linked Polyethylene (XLPE):

XLPE insulation offers superior thermal and mechanical properties compared to traditional PE insulation. It is often the preferred choice for high-voltage power transmission and distribution systems due to its ability to withstand high temperatures and environmental stresses. XLPE insulation is highly resistant to heat, making it suitable for long-term operation in demanding environments.

PVC (Polyvinyl Chloride):

PVC insulation is a versatile option that provides good electrical insulation properties at a relatively low cost. It is widely used in various applications, including building wiring, automotive cables, and consumer electronics. PVC insulation is available in flexible and rigid forms, offering flexibility in design and installation.

Rubber:

Rubber insulation is highly flexible and durable, making it ideal for applications that require frequent bending or movement, such as portable power cords and industrial machinery. Rubber insulation offers excellent resistance to abrasion, oils, and chemicals, making it suitable for harsh operating conditions. It is commonly used in mining, construction, and marine applications where reliability is crucial.

Factors Influencing Insulation Performance

Several factors can significantly impact the performance and longevity of cable insulation:

Voltage Rating

The insulation material must have a voltage rating that matches or exceeds the operating voltage of the electrical system to prevent breakdown and ensure safety. Choosing insulation with the appropriate voltage rating is critical to avoid insulation failure and potential safety hazards. Insulation materials undergo rigorous testing to determine their voltage withstand capabilities, ensuring compliance with industry standards and regulations.

Environmental Conditions

Environmental factors such as temperature variations, moisture, chemicals, and UV exposure can gradually degrade insulation over time, leading to insulation failure and compromised cable safety. Selecting insulation materials that are resistant to these environmental stresses is essential for ensuring long-term reliability. Environmental testing and accelerated aging studies help evaluate the performance of insulation materials under various conditions, guiding the selection process for specific applications.

Mechanical Stress

Cables subjected to mechanical stress, such as bending, twisting, or vibration, require insulation that can withstand these forces without cracking or deteriorating. Flexible and durable insulation materials, such as rubber, are often preferred for applications where mechanical stress is a concern. Mechanical testing, including tensile strength and flexural endurance tests, assesses the mechanical properties of insulation materials, ensuring they meet the requirements of the intended application.

Installation Practices

Proper installation techniques, including cable routing, bending radius, and securing methods, are crucial for preserving insulation integrity and preventing damage during installation and maintenance. Careless installation practices can lead to insulation damage, compromising cable safety and performance. Training and certification programs educate installers on best practices for handling and installing cables, minimizing the risk of insulation-related issues.

Importance of Proper Insulation for Cable Safety and Performance

Ensuring that cables are properly insulated is paramount for maintaining electrical safety and system reliability. Proper insulation protects against electrical faults, insulation breakdown, and other potential hazards, reducing the risk of fires, equipment damage, and personal injury. By selecting the right insulation material and following best practices for installation and maintenance, engineers can design and maintain electrical systems that meet the highest safety standards and provide reliable operation.

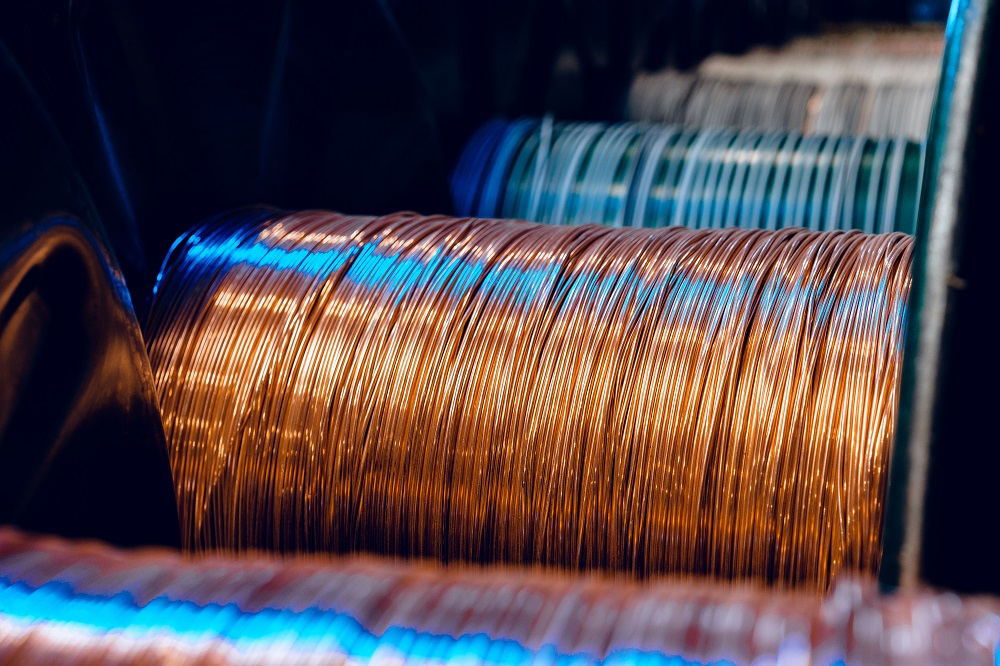

About Pure CU: Wires and Cables

At Pure CU, we take pride in being a leading provider of fire and heat-resistant wires and cables, ensuring quality, reliability, and innovation since 1984. Based in Karachi, we are dedicated to delivering superior electrical solutions crafted with advanced manufacturing techniques and backed by four decades of expertise. Trust Pure CU to power your needs with products designed for excellence and safety.

Conclusion

In conclusion, insulation plays a vital role in ensuring the performance, reliability, and safety of cables in electrical systems. By understanding the different types of insulation materials, factors influencing insulation performance, and the importance of proper insulation selection and installation, engineers can design and maintain electrical systems that meet the highest safety standards and provide reliable operation. With ongoing advancements in insulation technology and rigorous testing standards, the future of cable insulation holds promise for even greater performance and safety enhancements.