In the intricate landscape of industrial settings, where efficiency and reliability are paramount, the installation of wires and cables plays a pivotal role. This blog delves into real-world case studies showcasing successful implementations, offering valuable insights into best practices and innovative approaches.

Understanding the Importance of Proper Installation

Ensuring Safety and Reliability

Proper installation practices are imperative to guarantee the safety and reliability of industrial operations. In our case studies, we delve into instances where meticulous attention to detail, including thorough inspections and adherence to safety standards such as NEC (National Electrical Code), not only mitigated risks but also enhanced overall safety standards. For example, in a manufacturing facility, the implementation of a comprehensive safety checklist for cable installation ensured compliance with regulatory requirements and minimized the likelihood of accidents.

Minimizing Downtime

Efficient installation procedures not only ensure safety but also minimize downtime, crucial for maintaining productivity in industrial settings. Through our case studies, we analyze strategies employed to streamline installation processes, resulting in minimal disruption to operations. This includes meticulous planning and scheduling to coordinate installation activities with production downtime windows. For instance, in a power plant upgrade project, the installation team worked collaboratively with plant operators to identify optimal time frames for cable replacement, minimizing downtime and maximizing productivity.

Implementing Advanced Technologies

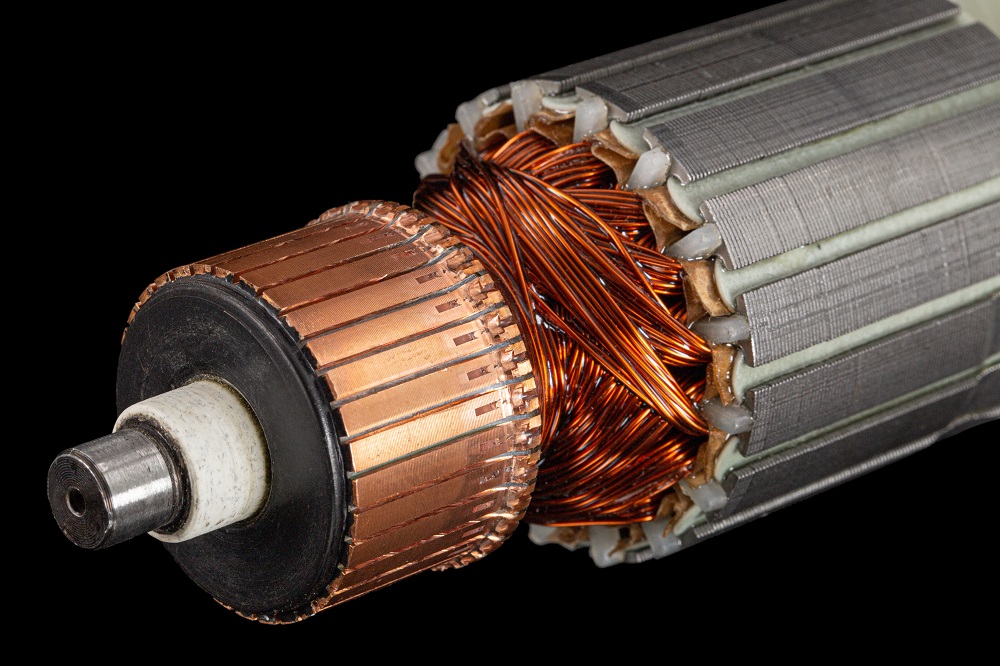

Harnessing Automation

Advancements in automation technology have revolutionized wire and cable installations. Our case studies highlight instances where automated systems, such as robotic cable laying machines and computer-aided design (CAD) software, were deployed to expedite installation processes while maintaining precision and accuracy. For example, in a large-scale industrial construction project, robotic cable laying machines were utilized to lay cables in hard-to-reach areas with speed and precision, reducing manual labor and minimizing installation time.

Leveraging IoT Solutions

The Internet of Things (IoT) has opened new avenues for optimizing industrial operations, including wire and cable installations. We explore how IoT-enabled solutions were utilized to monitor installation parameters in real-time, ensuring compliance with industry standards. In a warehouse automation project, IoT sensors were integrated into cable trays to monitor temperature, humidity, and vibration levels, providing early warning alerts for potential issues and enabling proactive maintenance interventions, thus enhancing the reliability and longevity of the installed cables.

Overcoming Challenges

Navigating Complex Environments

Industrial settings often present complex environments, posing challenges during wire and cable installations. Our case studies shed light on innovative approaches employed to navigate these challenges, from dealing with confined spaces to addressing environmental factors. For instance, in an offshore oil rig project, specialized cable installation techniques were employed to navigate harsh marine environments and extreme weather conditions, ensuring the reliability of critical electrical connections.

Adapting to Unique Requirements

Every industrial setting comes with its own set of unique requirements and constraints. Through real-world examples, we examine how flexibility and adaptability were key in successfully meeting these challenges during wire and cable installations. In a data center expansion project, modular cable management systems were employed to accommodate future growth and changes in equipment layout, providing scalability and flexibility to the installation while minimizing disruption to ongoing operations.

Ensuring Long-Term Sustainability

Future-Proofing Installations

In a rapidly evolving industrial landscape, future-proofing wire and cable installations is essential to ensure long-term sustainability. Our case studies delve into strategies adopted to incorporate scalability and flexibility, allowing for seamless adaptation to future needs. For example, in a renewable energy project, the use of high-quality, durable cables with ample capacity for future expansion ensured that the installation could accommodate increased power generation capacity over time, without the need for costly upgrades or replacements.

Prioritizing Maintenance and Upkeep

Sustainability extends beyond the initial installation phase, emphasizing the importance of ongoing maintenance and upkeep. We explore how proactive maintenance protocols were established, ensuring optimal performance and longevity of wire and cable systems. In a manufacturing facility, routine inspections and preventive maintenance programs were implemented to identify and address potential issues before they escalate, minimizing the risk of unplanned downtime and maximizing the lifespan of installed cables.

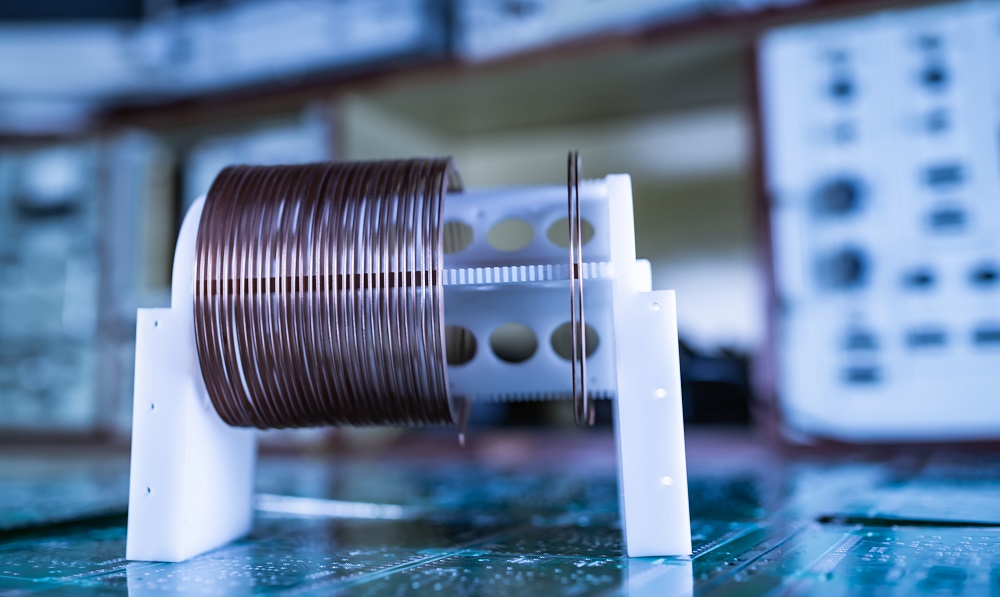

About Pure CU: Wires and Cables

At Pure CU, we take pride in being a leading provider of fire and heat-resistant wires and cables, ensuring quality, reliability, and innovation since 1984. Based in Karachi, we are dedicated to delivering superior electrical solutions crafted with advanced manufacturing techniques and backed by four decades of expertise. Trust Pure CU to power your needs with products designed for excellence and safety.

Conclusion

In conclusion, successful wire and cable installations in industrial settings are not merely about connecting components but rather a strategic endeavor aimed at enhancing safety, efficiency, and sustainability. By learning from real-world case studies and embracing innovative approaches, industries can pave the way for seamless operations and enduring success.

With a thorough understanding of the challenges and opportunities inherent in wire and cable installations, industrial enterprises can navigate the complexities of their environments with confidence and precision.